PT300 D:MINE

PT300 D:MINE: DEMINING, EOD/IEDD, BAC MACHINE

ATTACHMENTS

EFFECTIVE

CLEARANCE

The PT300 D:MINE machine is certified with a demining tiller and a demining flail according to the CWA/15044:2009 and HRN 1142:2009 to clear antipersonnel-mines (AP) and antitank-mines (AT).

Equipped with excavation and lifting arm and video cameras, it provides outstanding support to minimize risks and support recovery efforts in high-threat and hazardous areas.

Clearance of landmines and Explosive Remnants of War

-

Demining

-

EOD/IEDD

-

BAC

PT300 D:MINE FEATURES

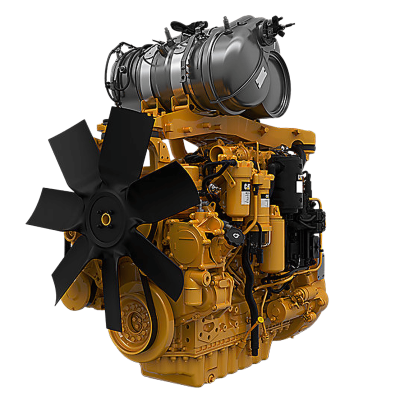

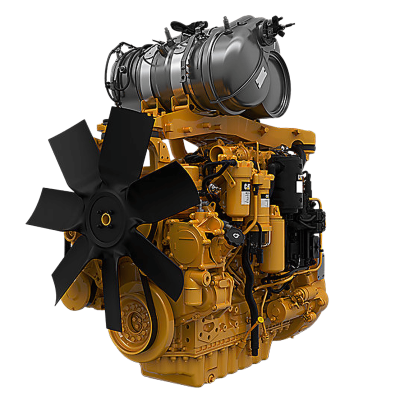

Tier 4 Final / Stage V Engine

You can count on the FAE PT300 D:MINE's engine. The Caterpillar C7.1 Acert inline six-cylinder engine is one of the world’s most popular and highly respected engines. Equipped with twin turbochargers with after cooler and Acert technology, the Tier 4 Final / Stage V version of this engine delivers an impressive 302 hp. Efficient, reliable, with superb consumption/power ratio.

Compliance with the Tier 4 Final / Stage V standard is guaranteed with the combination of diesel particulate filter (DPF), selective catalytic reduction (SCR) and diesel oxidation catalyst (DOC) technologies.

A combination that maximizes uptime and requires minimal maintenance over time, achieved by passive regeneration that does not require interrupting the work.

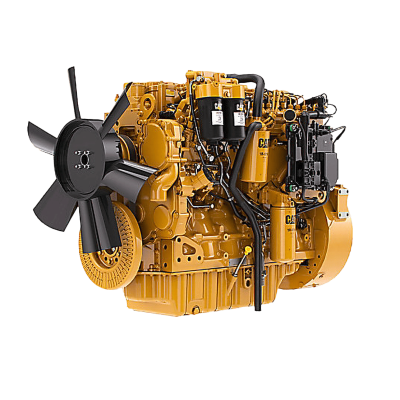

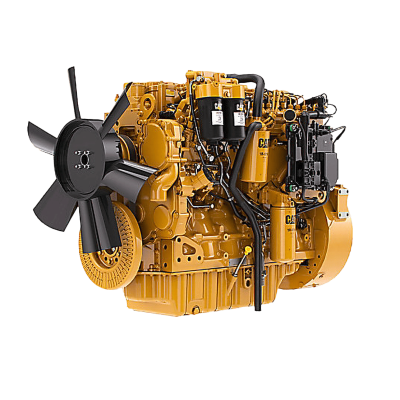

Tier 3 / Stage III Engine

The FAE PT300 D:MINE is also available in a Tier 3 / Stage III A version for emission-free markets, rated at 275 hp.

The generous 7-liter displacement and a cooling system designed specifically for the FAE PT300 D:MINE ensure that both configurations can offer peak performance in both heavy-duty applications and when working in tropical climes.

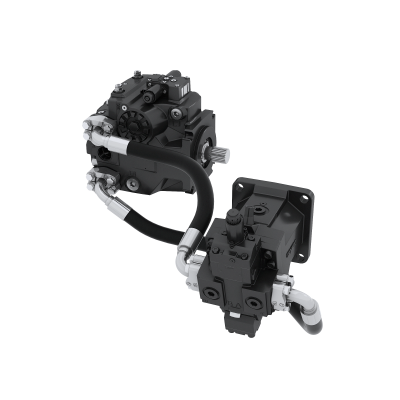

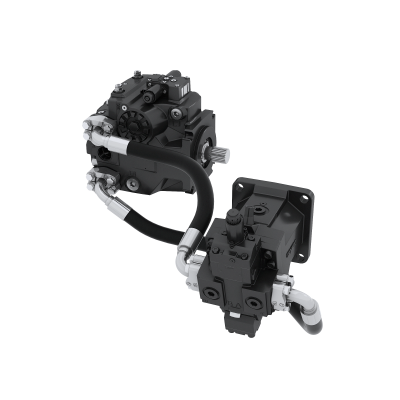

Transmission

The transmissions designed for the FAE PT300 D:MINE are based on two fundamental concepts: technology and integration. Electronically-controlled pumps and sensors and a dedicated control unit, work together to deliver maximum performance. The systems are designed to enable the CAT C7.1 Acert engine to operate at optimal rpms at all times.

The FAE PT300 D:MINE’s hydrostatic transmission also serves to dampen operating loads. This ensures that the carrier and its key components are subjected to less stress, reducing wear and tear. The final result is a longer duration over time.

An added benefit of the FAE PT300 D:MINE's hydrostatic transmission is that it can accommodate a wide variety of FAE demining equipment as well as forestry mulchers, stump cutters, and dozer blades.

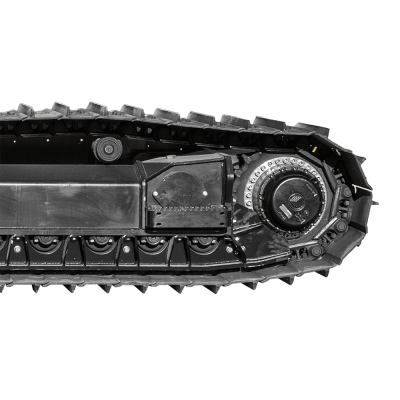

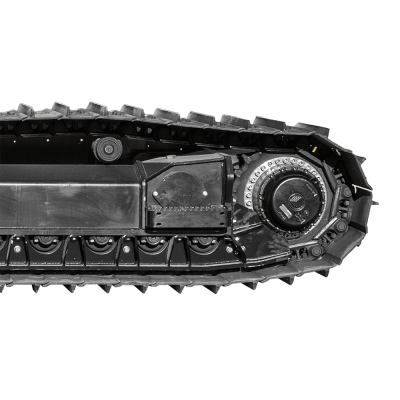

Undercarriage

Remote Control

COMPLETE

YOUR PRODUCT

Rear winch with 6-t traction force

Oil top-off pump (service package)

Chain guide

Service light (service package)

Rock guards

Pre-heating system for engine and hydraulic oil

Cab (full optional)

Custom color

360° I/R view cameras system

Additional rubber pads

Proportional and reversible radiator fan

CTRO Certifications

GET

IN TOUCH

Request sent

The request has been sent correctly. We’ll answer you as soon as possible.